Products

Professional manufacturer in electronic wire,magnetic wire, as well as wire & cable production equipments

Products

Contact Details

- Tel : +86-13402519623

- Whatsapp : +86 134 025 19623

- E-mail : listrong@listrong.cn

- Office: Suzhou Listrong Imp & Exp Co.,Ltd

- Add: Room 3524 Bldg.23 Greenland Kanhu Life Plaza , SSTT, Suzhou New District,JiangsuProvince,China

- Plant: Jiangsu Listrong Mechanical & Electrical Co.,Ltd

- Add: North JinfengRoad,Precision Machinery Manufacturing Industrial Park,DongtaiCity,JiangsuProvince,China

Please contact us through the following contact information.

Can't find the product you want? Please do a quick search.

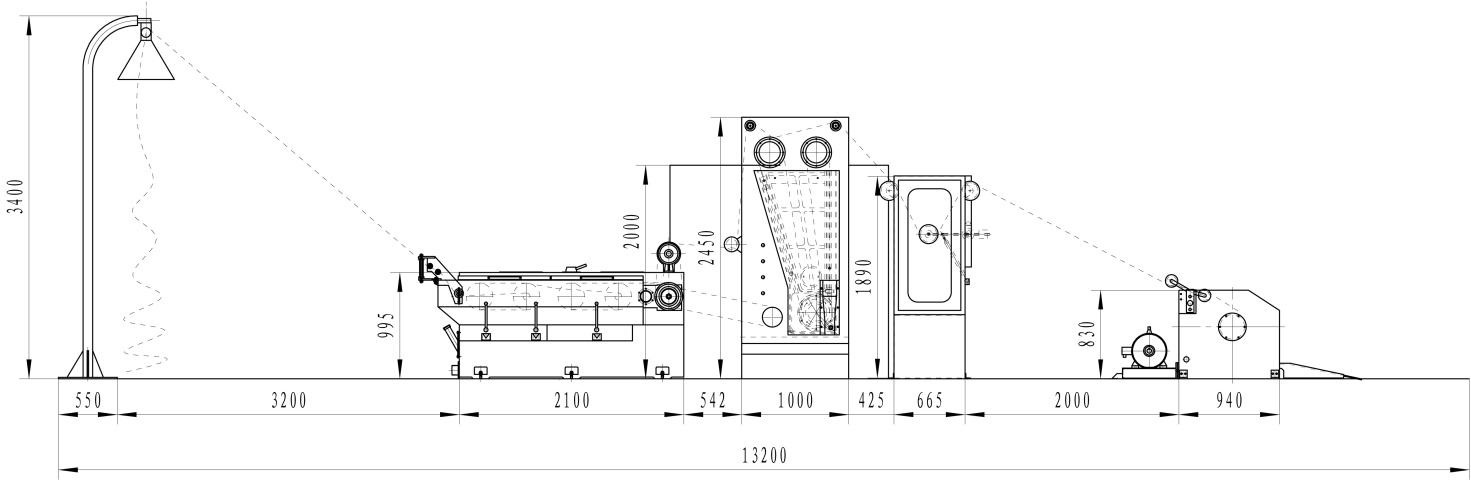

Medium wire drawing machine with annealer

Inlet: φ3.5-φ2.5mm

Outlet: φ1.6-φ0.4mm

Max. number of drawing dies:17

Max.speed: 1800mpm

Product introduction

|

Serial No. |

Item Name |

Qtty. |

|

1 |

Pay-off stand |

1 set |

|

2 |

17DS Main drawing machine |

1 set |

|

3 |

Annealing machine |

1 set |

|

4 |

Tension controller |

1 set |

|

5 |

WS630 Take-up machine |

1 set |

|

6 |

Pointer |

1 set |

|

7 |

Console |

1 set |

|

8 |

Main machine electrical cabinet |

1 set |

|

9 |

Annealing electrical cabinet |

1 set |

|

10 |

Steam generator |

1 set |

Technical parameters

Model: LISTRONG-17DST Intermediate wire drawing machine (copper)

|

Serial No. |

Item |

Description |

|

1 |

Inlet wire |

φ3.5-φ2.5mm |

|

2 |

Outlet wire |

φ1.6-φ0.4mm |

|

3 |

Max speed of drawing |

25m/s |

|

4 |

Drawing capstans |

Coated by tungsten carbide |

|

5 |

Max number of passes |

17 |

|

6 |

Main motor power |

55kw |

|

7 |

Take-up motor power |

15kw |

Machine structure

FAQ

Packing & Delivery

Production Workshop

- Client Feedback

- Please leave us a message, we will get in touch with you as soon as possible.

Follow Us

Signup for our newsletter to stay

up-to-date on our promotions, discounts,

sales, special offers and more.

- Office : Suzhou Listrong Imp & Exp Co.,Ltd Add: Room 3524 Bldg.23 Greenland Kanhu Life Plaza , SSTT, Suzhou New District,JiangsuProvince,China

- Plant : Jiangsu Listrong Mechanical & Electrical Co.,Ltd Add: North JinfengRoad,Precision Machinery Manufacturing Industrial Park,DongtaiCity,JiangsuProvince,China

- Mob./Whatsapp/Wechat : +86-13402519623 ( Ms Erica Liu )

- E-mail : listrong@listrong.cn