Products

Professional manufacturer in electronic wire,magnetic wire, as well as wire & cable production equipments

Products

Contact Details

- Tel : +86-13402519623

- Whatsapp : +86 134 025 19623

- E-mail : listrong@listrong.cn

- Office: Suzhou Listrong Imp & Exp Co.,Ltd

- Add: Room 3524 Bldg.23 Greenland Kanhu Life Plaza , SSTT, Suzhou New District,JiangsuProvince,China

- Plant: Jiangsu Listrong Mechanical & Electrical Co.,Ltd

- Add: North JinfengRoad,Precision Machinery Manufacturing Industrial Park,DongtaiCity,JiangsuProvince,China

Please contact us through the following contact information.

Can't find the product you want? Please do a quick search.

25/4DT Fine wire drawing machine with continuous annealing

2) Inlet dia.: 4×Φ1.50mm ~ Φ2.00mm

3) Outlet dia.: 4×Φ0.15mm ~ Φ0.50mm

4)Max. number of drawing dies:25pcs*4

Product introduction

1)Driven by high precise helical gears; particular oil lubrication mechanism; dual motors drive.

2)The capstan and die lubrication system is in emulsion spraying with force from inside of die holders design; In this way, the lubrication is more sufficient and it save space, moreover, it makes operation more convenient.

3)Annealing contact copper rings, nickel tubes are made from special alloy; it can ensure a longer service life.

4)The annealer control system is in zero length preset voltage design, so that it can ensure stable annealing of wires in the process of machine start and stop.

Technical Parameter

| Inlet dia. | 4*Φ1.5mm-Φ2.0mm |

| Outlet dia. | 4*Φ0.15mm-Φ0.5mm |

| Max.speed | 1800mpm |

| Max.number of drawing dies | 25 |

| Slip ratio of M/C | 16% |

| Fix speed capstan slip ratio | 8% |

| Main machine power | 55KW+18.5KW |

| Annealing power | 1200A 70V(84KVA) |

| Take up power | 11KW |

| Correction system | Automatically control |

| Annealing method | DC three-section annealing |

| Suitable spool | Φ630mm/Max. |

| Take up capacity | 500KG |

| Brake | Pneumatic brake |

| Machine dimension | 5000L*1600W*2100H(mm) |

|

Machine weight |

4000KGS |

Details

| S/N | Components | Picture |

| 1 | Main machine part |

|

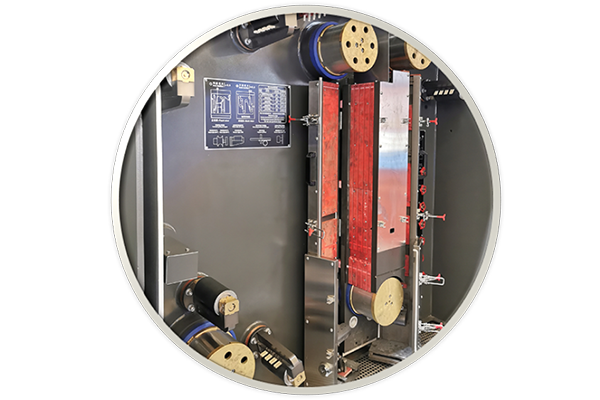

| 2 | Annealing part |

|

| 3 | Spooler |

|

| 4 | Overview |

|

- Client Feedback

- Please leave us a message, we will get in touch with you as soon as possible.

Follow Us

Signup for our newsletter to stay

up-to-date on our promotions, discounts,

sales, special offers and more.

- Office : Suzhou Listrong Imp & Exp Co.,Ltd Add: Room 3524 Bldg.23 Greenland Kanhu Life Plaza , SSTT, Suzhou New District,JiangsuProvince,China

- Plant : Jiangsu Listrong Mechanical & Electrical Co.,Ltd Add: North JinfengRoad,Precision Machinery Manufacturing Industrial Park,DongtaiCity,JiangsuProvince,China

- Mob./Whatsapp/Wechat : +86-13402519623 ( Ms Erica Liu )

- E-mail : listrong@listrong.cn